About the online seminar

In Thailand, the integration of Modern Systems with MES (Manufacturing Execution Systems) and APS is becoming increasingly relevant as industries strive to modernize their operations and stay competitive in the global market. Therefor the industrial manufacturing, food and beverage, pharmaceuticals including with logistics and supply chain will be the key targets and get benefits from this changing

This online seminar aims to explore the evolving landscape of planning and scheduling in modern industrial systems, focusing on the integration of Manufacturing Execution Systems (MES) and Advanced Planning and Scheduling (APS). The session will provide in-depth insights into how these integrative solutions can enhance operational efficiency, improve production quality, and drive competitive advantage

Organized by:

Supported by:

Highlight at the seminar

Date and Time

1. Introducing MES and APS

- Definition and importance of MES and APS in industrial plants

- Integrating MES and APS systems to increase production efficiency

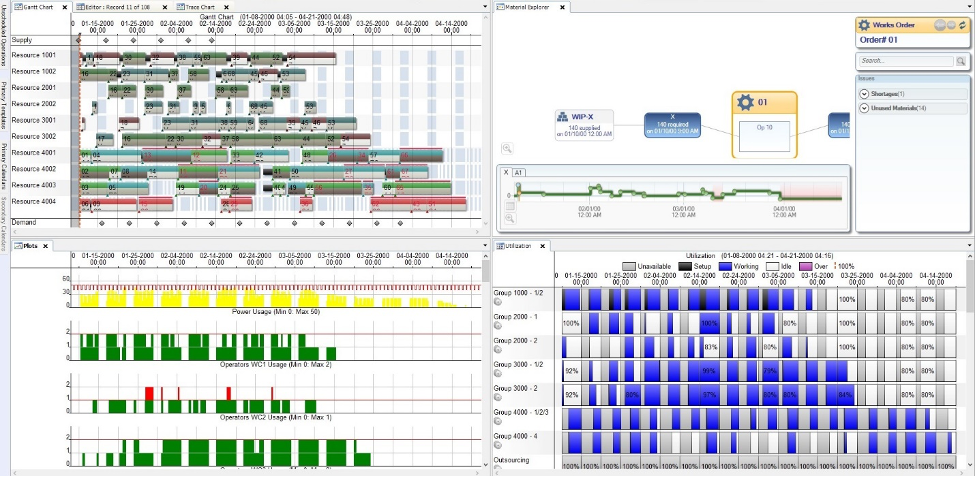

2. Using Siemens Opcenter APS

- Features and functions

- Steps for use

3. Structure (Architecture) of MES and APS

- Connection and data management

- Process control and production management

- Data analysis and report creation

4. Benefits and impacts of using MES and APS

- Increased production efficiency

- Efficient resource management

- Accurate and timely decision making

5. Case studies and application examples

- Practical use of Siemens Opcenter APS in industrial plants

- Results from using MES and APS systems

6. Q&A

- 11th (Wed) September 2024

- @ 15:00 – 16:30 น.

- ทาง Zoom Webinar

- Thai language only

Special privileges for seminar participants

- (Free) Online consultation for production planning

- (Free) On-site consultation to customer factory

- (Free) Lecture Materials

**Company and personal information of this seminar’s attendees will be shared between organizer and related companies

Benefits that seminar participants will receive from the seminar

➊ In-depth understanding of MES and APS and integration of these systems.

➋ Knowledge of using Siemens Opcenter APS to increase production efficiency.

➌ Techniques and strategies for planning and controlling production.

➍ Effective decision-making and resource management in the production process.

➎ Opportunity to exchange knowledge and experiences with experts and seminar participants.

➋ Knowledge of using Siemens Opcenter APS to increase production efficiency.

➌ Techniques and strategies for planning and controlling production.

➍ Effective decision-making and resource management in the production process.

➎ Opportunity to exchange knowledge and experiences with experts and seminar participants.

This seminar will focus on the critical role of integrating MES and APS in modernizing Thai industries. Participants will learn about the latest advancements, successful implementations, and the tangible benefits of adopting these technologies

Lectures by

This seminar is recommended for individuals who:

- Executives and managers in the production line

- Engineers and production experts

- Production Planning Manager

- Manager of IT and Data Management

- Expert in quality and process improvement

- Those interested in improving production processes and resource management in industrial plants

- Industrial manufacturers (automotive, electronics, textiles)

- Food and beverage companies

- Pharmaceutical manufacturers

- Logistics and supply chain professionals

For more detail information of solution, please check here

SIEMENS Opcenter APS provided by DENTSU SOKEN (THAILAND) LIMITED

Opcenter APS (Advanced Planning and Scheduling) is Siemens' solution designed to enhance manufacturing operations by providing advanced planning and scheduling capabilities. The primary targets for using Opcenter APS today will be help you with these

① Improved Production Efficiency:

⋆ Optimize production schedules to maximize resource utilization and minimize downtime

⋆ Streamline processes to reduce lead times and improve throughput

② Enhanced Decision-Making:

⋆ Use real-time data to make informed decisions quickly

⋆ Improve responsiveness to changes in demand, supply chain disruptions, and other variables

⓷ Cost Reduction:

⋆ Lower operational costs by optimizing inventory levels and reducing waste

⋆ Improve labor efficiency and reduce overtime costs

⓸ Quality and Compliance:

⋆ Ensure consistent product quality by maintaining optimal production schedules

⋆ Comply with industry standards and regulations through precise planning and tracking

⓹ Customer Satisfaction:

⋆ Improve on-time delivery rates by accurately predicting and meeting production deadlines

⋆ Enhance flexibility to meet changing customer demands

⋆ Optimize production schedules to maximize resource utilization and minimize downtime

⋆ Streamline processes to reduce lead times and improve throughput

② Enhanced Decision-Making:

⋆ Use real-time data to make informed decisions quickly

⋆ Improve responsiveness to changes in demand, supply chain disruptions, and other variables

⓷ Cost Reduction:

⋆ Lower operational costs by optimizing inventory levels and reducing waste

⋆ Improve labor efficiency and reduce overtime costs

⓸ Quality and Compliance:

⋆ Ensure consistent product quality by maintaining optimal production schedules

⋆ Comply with industry standards and regulations through precise planning and tracking

⓹ Customer Satisfaction:

⋆ Improve on-time delivery rates by accurately predicting and meeting production deadlines

⋆ Enhance flexibility to meet changing customer demands

- Effective planning and management of production in a short period of time It is an important tool in competition, allowing solutions for production planning to meet the needs of efficient production lines. By connecting the production process with accurate information through the Digital Platform

- Simplify and increase efficiency in production planning under actual production conditions Therefore, problems can be seen and solutions can be assessed in advance

- Helps reduce costs and time used in production. to analyzing the production process efficiently in Realtime, reducing errors and communication time between operators Leads to better efficiency and productivity

Company Information

[Organizer]

Dentsu Soken (Thailand) Limited Business: IT system development, integration and sales https://www.th.dentsusoken.com/th/

[Seminar Operation]

NC Network Asia Co., Ltd. Business: Business matching, Business Media http://u-machine.net/th/company/

Let's learn together with industry experts!

Education is the passport to the future, for tomorrow belongs to those who prepare for it today.